Compressed air piping systems are essential infrastructure in many industrial, commercial, and residential settings. These systems deliver compressed air — air pressurized above atmospheric levels — to power tools, equipment, and essential processes across industries.

Understanding how air piping systems work, the role of their components, and the importance of selecting the right materials can significantly improve system efficiency, safety, and operational longevit

Uses of Compressed Air Piping Systems

Compressed air serves as a flexible, reliable energy source across multiple sectors, including:

-

Industrial manufacturing (e.g., powering pneumatic tools, conveying materials)

-

HVAC systems (e.g., control systems, air handling units)

-

Refrigeration systems

-

Automotive and transportation (e.g., braking systems, tire inflation)

-

Aerospace industry (e.g., aircraft control and maintenance operations)

-

Food and beverage processing (e.g., bottling, packaging equipment)

A properly designed air piping network ensures that compressed air reaches the right points at the correct pressure with minimal losses, making operations more efficient and cost-effective.

Major Components of a Compressed Air Piping System

Every air piping system includes several critical components that work together to deliver reliable performance:

| Component | Function |

|---|---|

| Compressor | Pressurizes atmospheric air for system use |

| Air Receiver Tank | Stores compressed air and regulates pressure levels |

| Air Cooler | Reduces the temperature of compressed air, removing moisture |

| Filters | Eliminate contaminants such as dust, oil, and water |

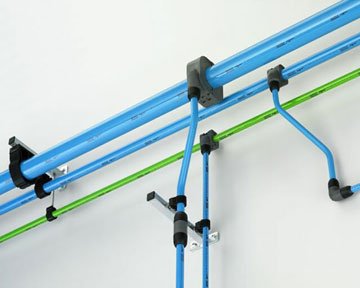

| Piping Distribution Network | Transports compressed air to various application points |

The distribution piping network is the backbone of the system, and its design directly influences the efficiency, safety, and energy consumption of the entire operation.

Why Proper Pipe Selection and Design Matter

The piping system’s design and material choice significantly impact the performance and reliability of the compressed air system. Poorly designed systems, or those using incorrectly sized pipes, face several challenges:

-

Reduced discharge pressure at end-use points

-

Increased energy consumption due to pressure drops

-

Frequent maintenance issues and premature system wear

-

Complete system failures in extreme cases

Proper pipe sizing, optimal routing, and minimizing bends and restrictions ensure that energy losses are minimized, maximizing the value and efficiency of the compressed air.

Pipe Materials Used in Compressed Air Systems

Choosing the right piping material is critical for system durability, safety, and efficiency. Common options include:

| Advantages | Considerations | |

|---|---|---|

| Steel (Black or Galvanized) | Strong, durable, widely available | Heavy; may corrode internally |

| Stainless Steel | Corrosion-resistant, long service life | Higher upfront cost |

| Aluminum | Lightweight, corrosion-resistant, easy to install | Ideal for clean environments |

| Copper | Excellent corrosion resistance, easy to solder | Expensive compared to other options |

| Plastic (e.g., PVC, CPVC) | Lightweight, easy installation | Not suitable for high-pressure applications; prone to bursting under pressure |

Important: Plastic piping systems are generally discouraged for compressed air because failure can result in catastrophic ruptures and serious safety hazards.

Metal piping — particularly stainless steel and aluminum — remains the preferred choice for industrial-grade compressed air systems due to their strength, reliability, and ability to handle higher pressures safely.

Importance of Professional Air Piping Systems Installation and Maintenance

A compressed air system is a complex, pressurized network. Errors in installation or material selection can:

-

Lead to major energy losses

-

Increase operating costs

-

Create serious safety hazards

-

Result in expensive system downtime

Professional services ensure that the system is designed according to:

-

Manufacturer specifications

-

Industry best practices

-

Local and national safety codes (e.g., ASME, CSA standards)

Regular preventive maintenance is equally important to:

-

Identify and fix leaks early

-

Check for corrosion or blockages

-

Maintain optimal system pressure and flow

-

Extend the lifespan of system components

Best Practices for Compressed Air System Maintenance

-

Inspect filters, drains, and pipes regularly to prevent clogging and moisture buildup

-

Test system pressure at various points to detect inefficiencies

-

Monitor compressor performance to detect early signs of wear

-

Drain air receiver tanks daily to remove accumulated moisture

-

Schedule professional audits annually for leak detection and energy optimization

Adhering to a maintenance checklist aligned with manufacturer recommendations ensures that compressed air systems run smoothly, safely, and cost-effectively.

Air Piping Systems – Conclusion

A well-designed and professionally maintained compressed air piping system is essential for efficient operations across industrial and commercial sectors. From choosing the right piping materials to ensuring precision in design and maintenance, every decision plays a crucial role in system performance, longevity, and safety.

Engaging experienced professionals for system design, installation, and routine maintenance ensures you get the maximum return on your investment while avoiding unexpected failures or costly downtime.

-

ThePiping.com: What Is Compressed Air Piping Systems? – ThePiping.com. https://thepiping.com/2023/07/what-is-compressed-air-piping-systems.html, July 2023.

-

Academia.edu: (PDF) Compressed Air Systems – Academia.edu. https://www.academia.edu/39832909/Compressed_Air_Systems, July 2019.

-

ControlGear.net: Guide to Choosing the Right Compressed Air Piping – ControlGear.net. https://www.controlgear.net/blog/guide-to-choosing-the-right-compressed-air-piping-system/, March 2025.

-

Springer: Management of Compressed Air to Reduce Energy Consumption – Springer. https://link.springer.com/chapter/10.1007/978-3-030-55190-2_16, August 2020.

-

Energy Management and Energy Efficiency in Industry (2021). Energy Management and Energy Efficiency in Industry (2021) – Academia.edu. https://www.academia.edu/43374599/Energy_Management_and_Energy_Efficiency_in_Industry

_2021, 2021.

Air Piping Systems FAQs

1. What is the primary purpose of a compressed air piping system?

A compressed air piping system delivers pressurized air from the compressor to various points of use in an industrial, commercial, or residential setting. It ensures that air is available at the correct pressure for powering tools, machines, and systems.

2. What materials are best for compressed air piping systems?

The most recommended materials are stainless steel, aluminum, and copper due to their strength, corrosion resistance, and ability to handle high pressures. Plastic piping is generally not recommended for compressed air due to safety concerns.

3. Why is proper pipe sizing important in compressed air systems?

Incorrect pipe sizing can cause significant pressure drops, energy losses, and reduced system efficiency. Properly sized pipes ensure adequate airflow with minimal pressure loss, reducing energy costs and equipment strain.

4. How often should a compressed air system be inspected?

A compressed air piping system should be inspected at least once a year. Regular maintenance includes checking for leaks, corrosion, blockages, and ensuring optimal pressure throughout the system.

5. Can I use PVC pipes for compressed air systems?

No. PVC pipes are unsafe for compressed air applications because they can shatter under pressure, causing dangerous flying debris. Only pressure-rated metals like steel or aluminum are considered safe for compressed air transport.